LSPP - Laboratory of simulation of flow processes

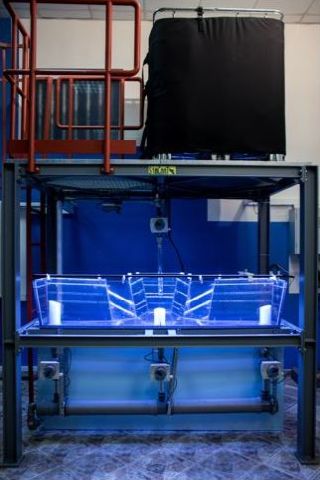

The history of physical modelling of continuous casting process has begun in 2004, when the water model of CCM was built in cooperation with U. S. Steel Košice, s.r.o. in Faculty of Metallurgy. The water model in scale 1:3 consist of two ladles, boat type of tundish with stopper rods and two molds. This model is fully computer controlled and enables to simulate steady-state and transient casting conditions.

The gradually obtaining of know-how in this area enabled to implement the model outputs to start a business with praxis home and abroad. Nowadays there is the routine cooperation between our scientist and steel plants and producers of refractory materials relating to the testing and development of CCM components and in practice of casting before its application in real CCM.

Physical model of the tundish for continuous steel casting of U.S.Steel Košice, s.r.o.

Physical model of the tundish for continuous steel casting of Železiarne Podbrezová, a.s. (SimConT)

The physical tundish model of the plant Železiarne Podbrezová, a.s. (SimConT) is a joint workplace of the Institute of Metallurgical Technologies and Digital Transformation (IMTech) and ŽP Research and Development Centre s.r.o.

The aim:

The laboratory SimConT is focused on the field of physical modeling research and the optimization of steel flow phenomena in the tundish of ŽP, a.s.

To solve current practice problems and the accelerated transfer of the research results into real CCM as a specific innovation projects.

To solve current practice problems and the accelerated transfer of the research results into real CCM as a specific innovation projects.

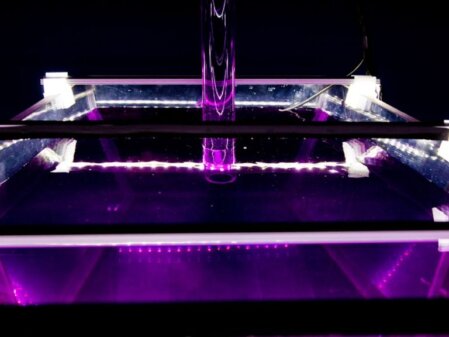

T-type tundish

The obtained know-how has been applied on the creation of shared water model laboratory relating to tundish of ŽP, a .s. The longstanding experience of our scientists enables to build the most modern, top-level laboratory, which is the major part of tundish metallurgy. The unique of this model consists in the control system, which is similar to real CCM and enables to control of all levels and flowages online, so it can simulate all operating conditions, including transient casting.

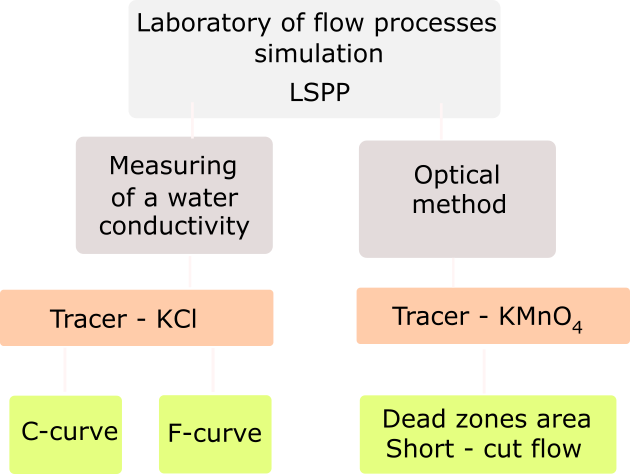

Method of measurement and evaluation of physical modelling results

The following two methodologies are used for measurement and evaluation in the LSPP laboratory.

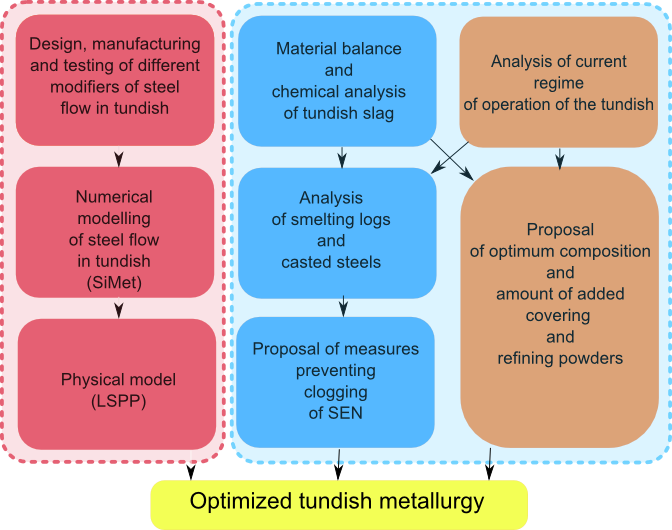

Schematic diagram of the tundish metallurgy optimization procedure